AI-Driven Defect Detection for Aerospace Composites

A Bachelor's Thesis from Bauman Moscow State Technical University, showcasing a novel methodology combining high-fidelity simulation with advanced AI.

The Challenge

Composite materials in aerospace are strong but susceptible to hidden defects. The goal was to develop a reliable method to detect these flaws and predict component lifecycle, moving beyond the limitations of traditional inspection.

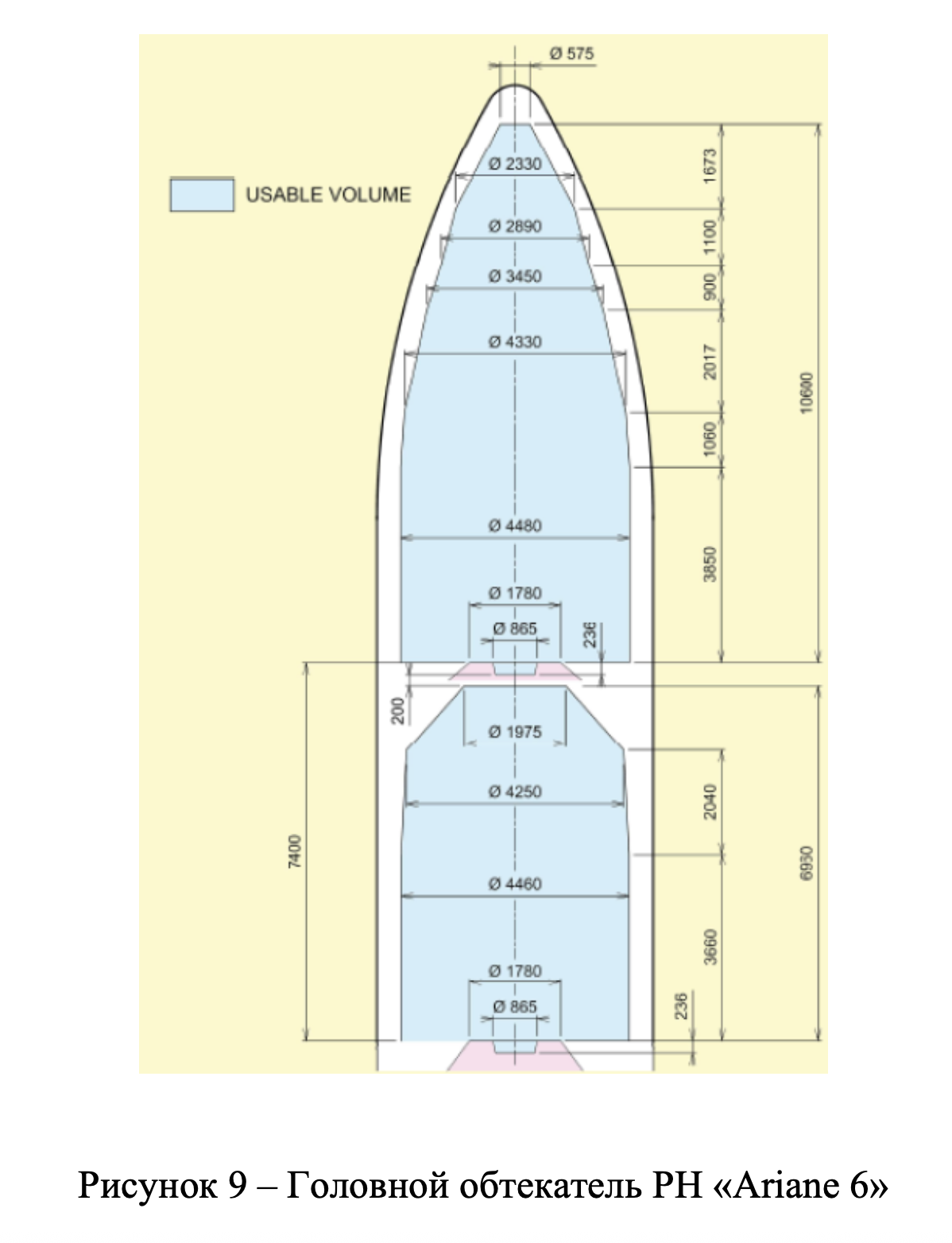

Project Subject: An Ariane 6 launch vehicle nose cone.

My Approach: Engineering the Data

From CAD to FEA Model

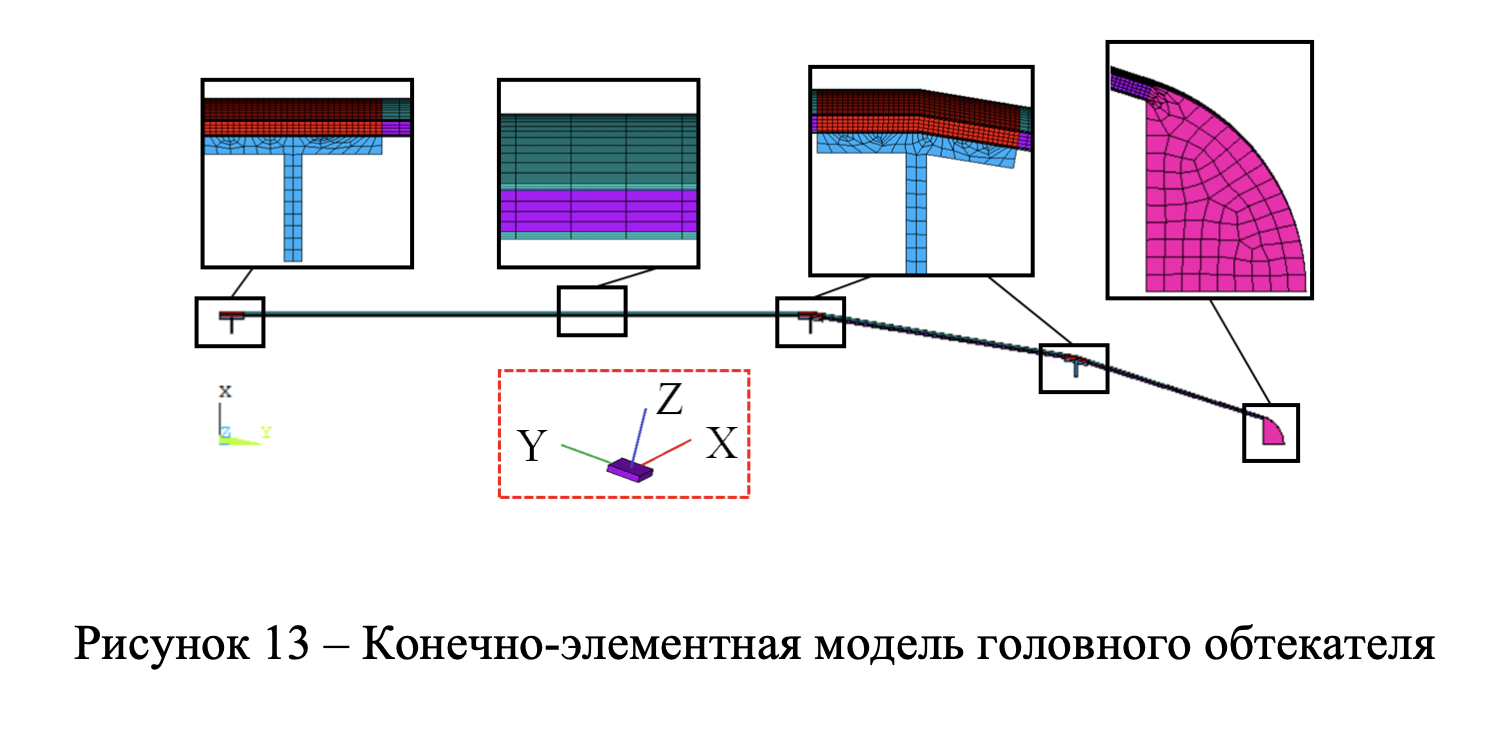

I began by constructing a high-fidelity Finite Element (FEA) model of the rocket fairing using ANSYS. This involved creating a detailed mesh to accurately represent its complex geometry and material properties.

Proprietary Dataset Generation

Instead of using off-the-shelf data, I simulated 100 unique defect scenarios. By applying realistic aerodynamic loads and thermal conditions, I generated a rich, proprietary dataset of stress and strain distributions—the perfect fuel for our AI model.

The detailed FEA mesh used for structural analysis in ANSYS.

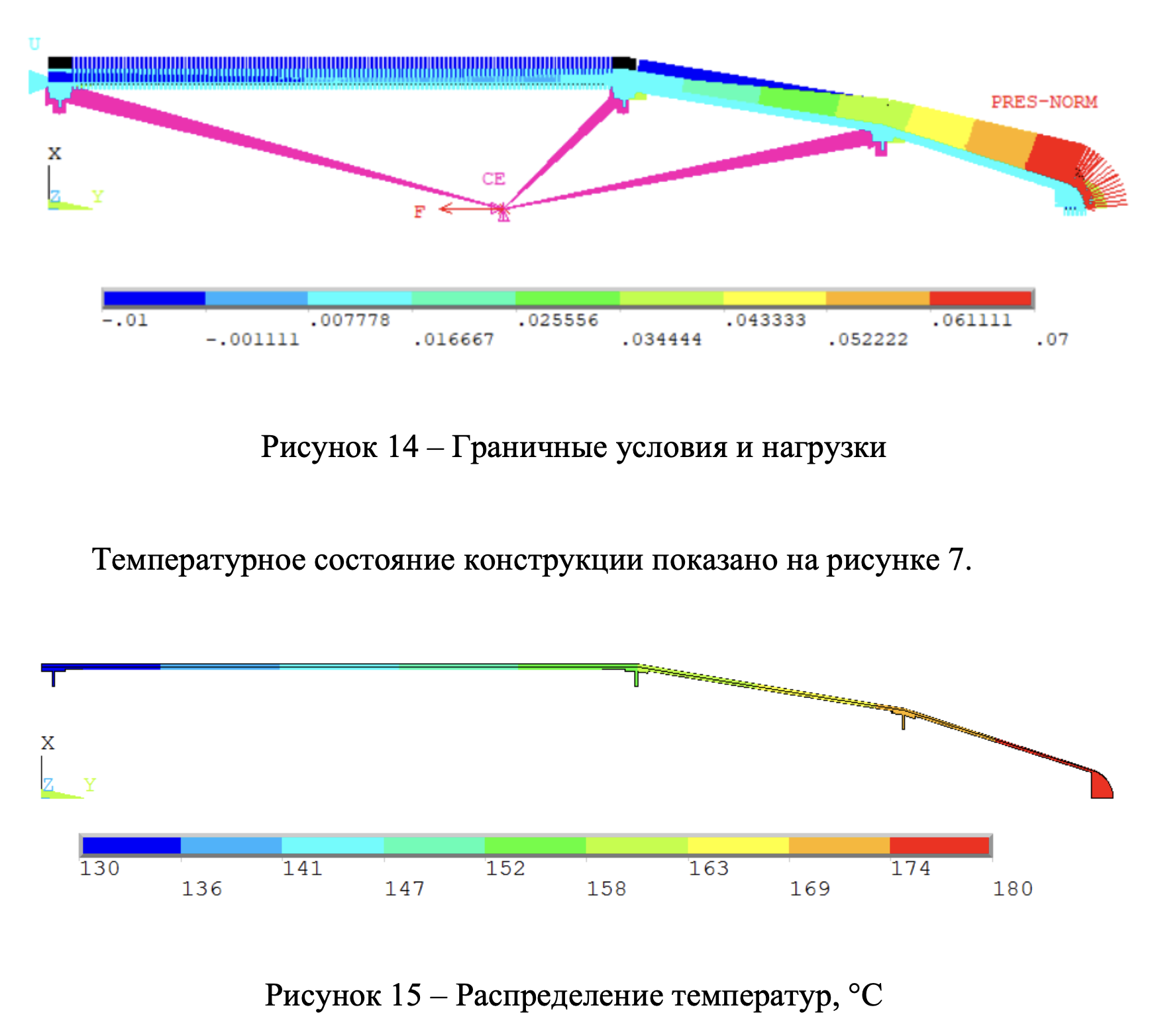

Simulation setup and boundary conditions in ANSYS.

Simulation Details & Boundary Conditions

Accurate simulation relies on meticulously defined boundary conditions and load applications. This image illustrates the various forces and constraints applied to the FEA model to mimic real-world operational scenarios, ensuring the fidelity of the generated data.

The Results: AI-Powered Prediction

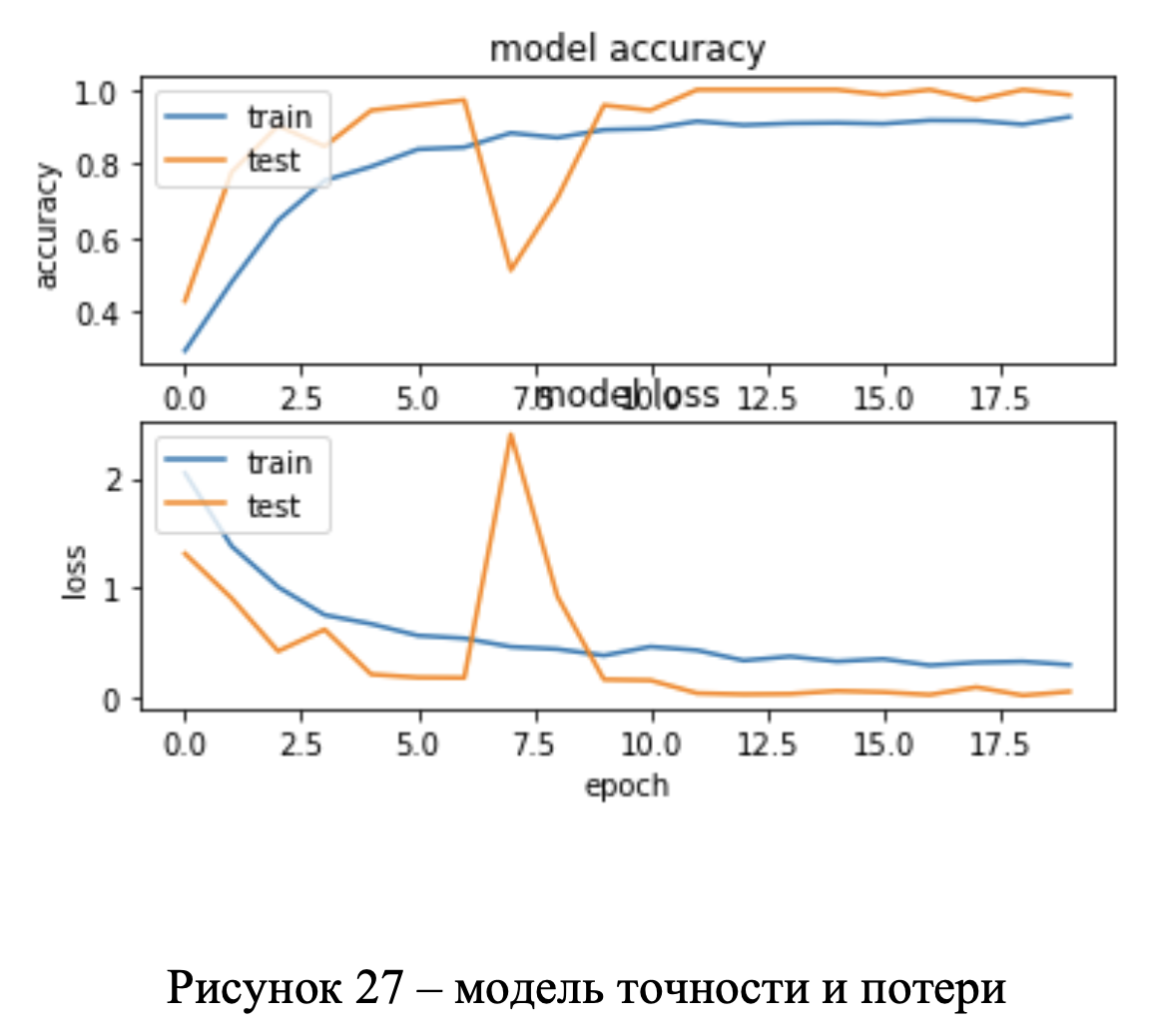

The trained models demonstrated exceptional performance, validating the entire methodology:

- The FEA-data model achieved 95% efficiency in predicting component lifecycle.

- The Computer Vision model attained 97% accuracy in identifying surface defects.

Training and validation accuracy/loss curves (Thesis, p. 79).

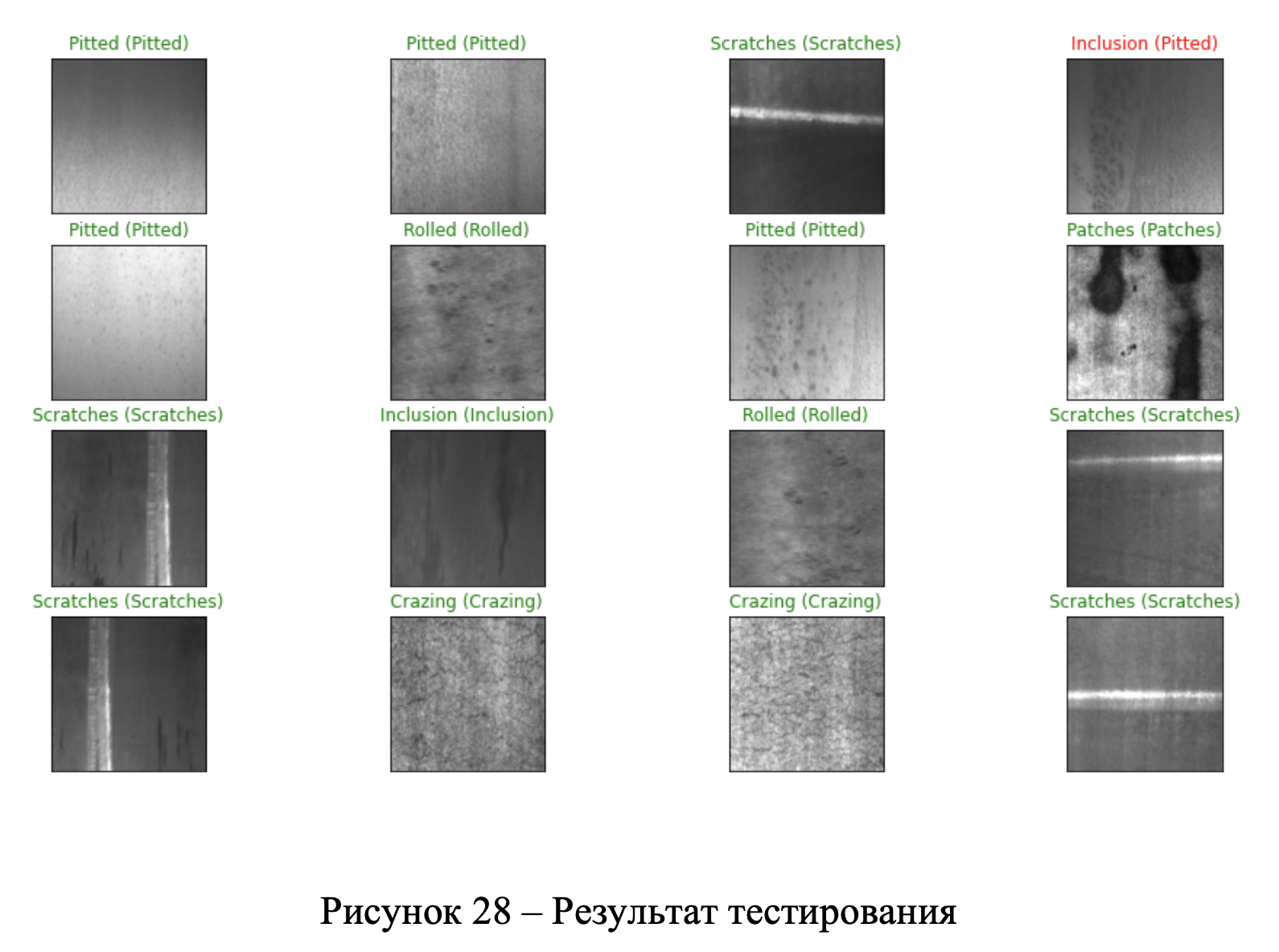

AI in Action: Visual Defect Classification

The Computer Vision model in action. Green labels indicate the AI's correct classification compared to the ground truth (in parentheses). The model successfully identifies various surface defects like pitting, scratches, and patches from raw images.

Sample classification results from the trained CNN model (Thesis, p. 80).

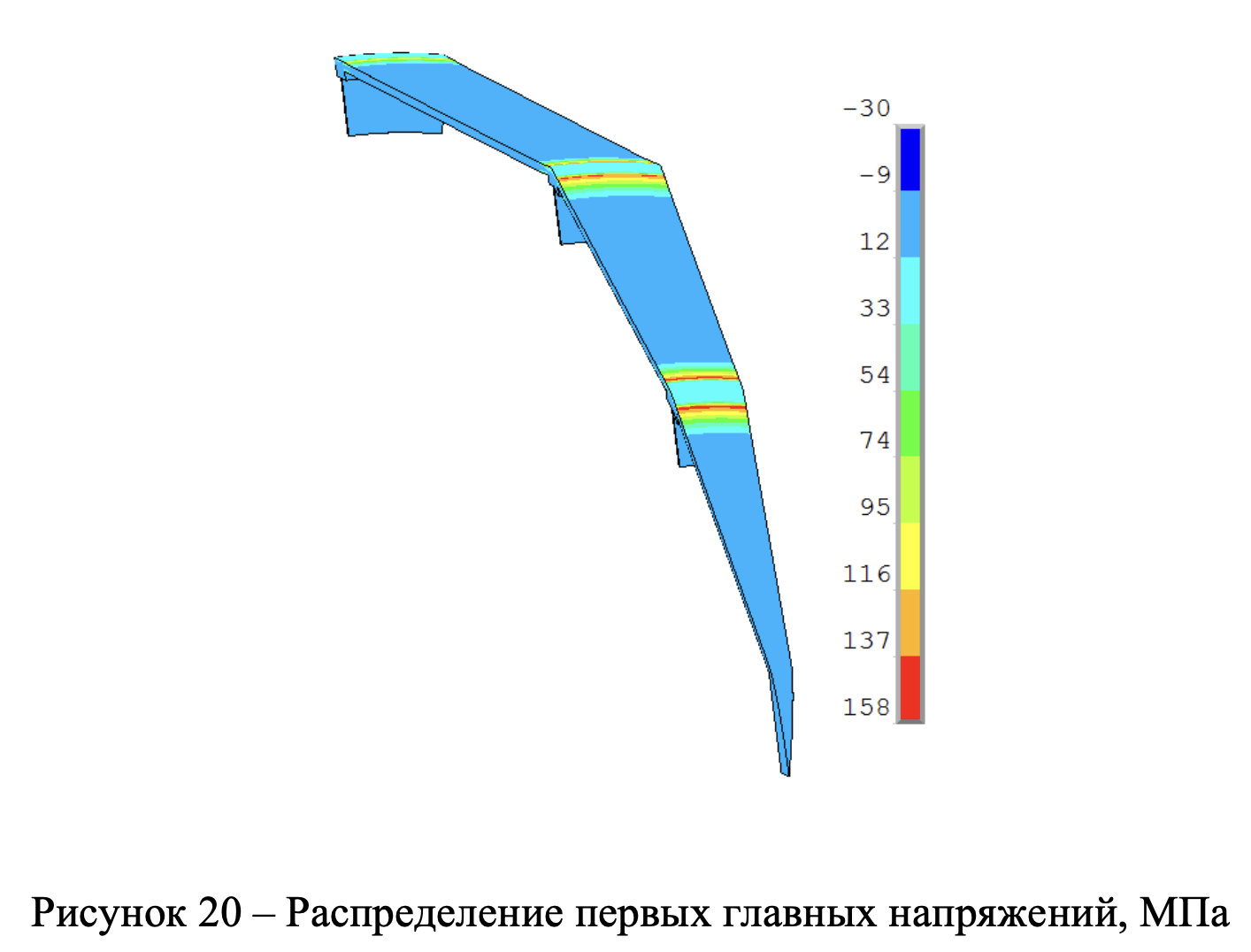

FEA Results & Insights

The Finite Element Analysis yielded critical insights into the structural behavior of the composite fairing under stress. This visualization displays the distribution of stresses within the component, highlighting areas of high concentration and potential failure points, which informed the predictive model.

Distribution of first principal stresses within the fairing (Thesis, p. 74).

Key Skills

Full Thesis & Citation

Development of AI-driven Defect Detection Methods for Aerospace Composite Structures

Myungeun Lee, C.V. Resnik, D.V. Sapronov

Download Full Thesis (PDF) →